Chip:

Air supply system

Air compressor unit

Gas supply system

Constant pressure water supply

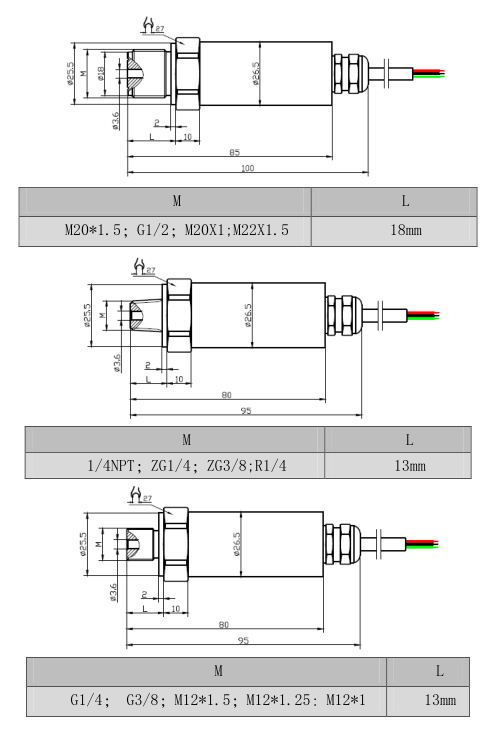

Process connection m20x1.5, G1 / 2, G1 / 4, ZG1 / 4, 1 / 4NPT

Product power supply 24VDC (range: 9-30vdc);

Product power supply 24VDC (range: 9-30vdc); It is strictly prohibited to use hard objects (such as screwdriver, finger, iron nail, etc.) to make the pressure core body under pressure measurement output;

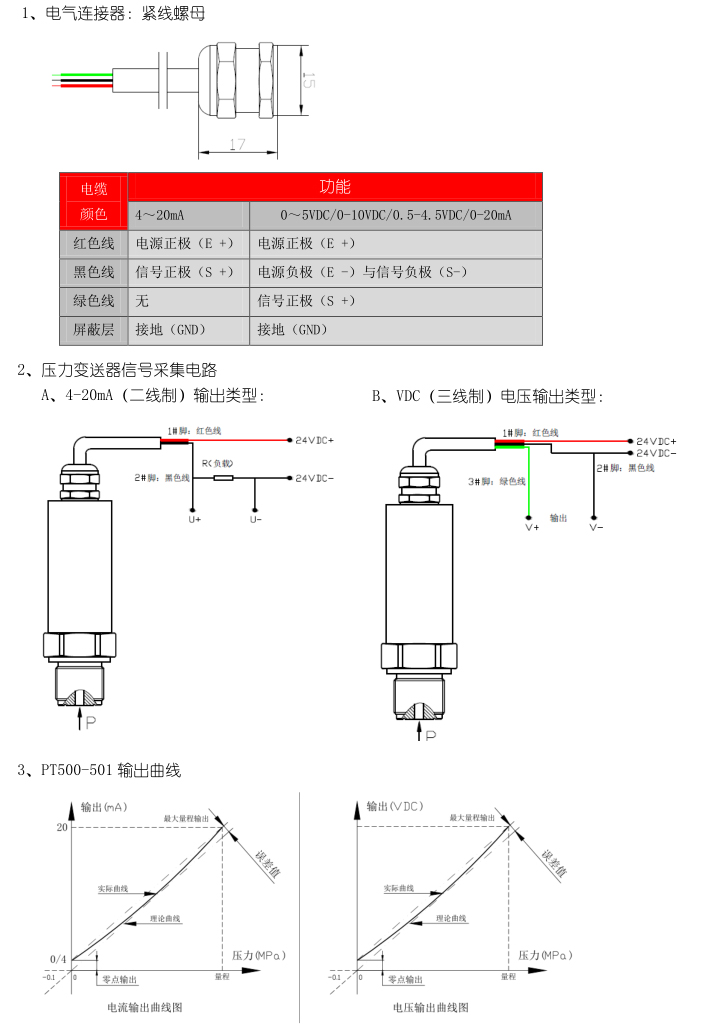

It is strictly prohibited to use hard objects (such as screwdriver, finger, iron nail, etc.) to make the pressure core body under pressure measurement output; The power and signal wires shall be correctly wired according to the specifications of the ordered products;

The power and signal wires shall be correctly wired according to the specifications of the ordered products; During product installation, the stressed part is "process connection hexagon wrench position", and the wrench specification corresponds to hexagon;

During product installation, the stressed part is "process connection hexagon wrench position", and the wrench specification corresponds to hexagon; It is strictly prohibited that the medium temperature, pressure range and excitation voltage of the tested system exceed the rated use range of the transmitter;

It is strictly prohibited that the medium temperature, pressure range and excitation voltage of the tested system exceed the rated use range of the transmitter; Pay attention to protect the outgoing cable of the transmitter. When the span is too large on site, it is recommended to use metal pipe for protection or overhead;

Pay attention to protect the outgoing cable of the transmitter. When the span is too large on site, it is recommended to use metal pipe for protection or overhead; The pressure transmitter is a precision measuring instrument, do not impose impact or smash to avoid damaging the core;

The pressure transmitter is a precision measuring instrument, do not impose impact or smash to avoid damaging the core; The product is installed in a ventilated, dry and non corrosive environment, and installed in the open with protective devices to avoid direct sunlight;

The product is installed in a ventilated, dry and non corrosive environment, and installed in the open with protective devices to avoid direct sunlight;Tel:0757-26619568 Fax: 0757-26619508

24-hour online technical support:13790092618

Cloud platform:www.puliangiot.com

Address:501, block 8, phase 5, Rongli tianfulai industrial city, Ronggui town, Shunde District, Foshan City