Product description of strain type pressure transmitter:

Chip:

Adopt imported voltage sensing chip; select the chip technology, with zero, full range compensation, temperature compensation;

Strain gauge core, high-strength elastic deformation pressure sensing material, equipped with temperature compensation, has the advantages of impact resistance and fatigue resistance;

Micromachining process, integrated structural design, integral elastic material, no welding process, 1000 MPa compression will not crack, to ensure the safety of the product;

Signal processing and output:

24 bit ADC sampling processing chip;

DSP digital signal conditioning algorithm;

Multipoint line temperature calibration;

Voltage and current overload protection;

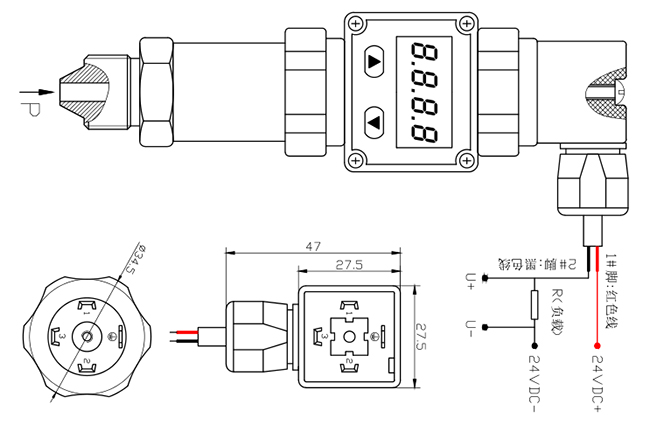

Standard industrial signal output: 4-20mA (two-wire system);

Four digit pressure indicator, display range: - 1999-9999, sampling rate: 10 times / S;

Structure:

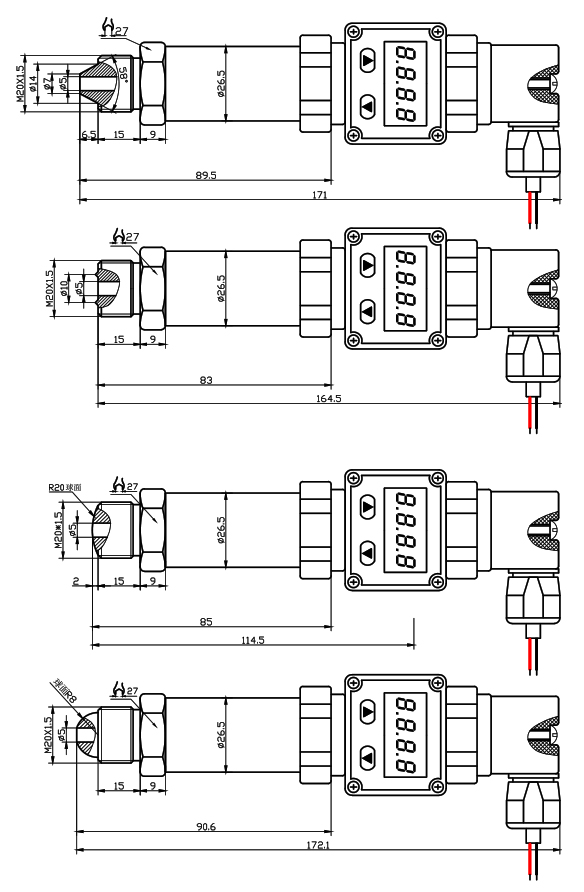

Small structure, full seal welding structure, impact resistance, fatigue resistance, high reliability, a variety of process connection;

Process connection material, 304, four sealing methods are optional: taper seal, end face seal, arc face seal and spherical seal;

Din43650 Hersman standard electrical connector;

Supporting standard four core shielded cable;

Application:

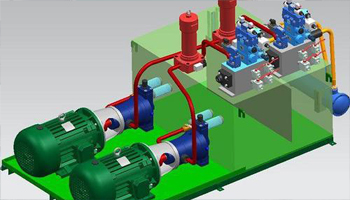

Pressure measurement of large hydraulic machinery and hydraulic station;

Pressure measurement and control of water cutter and ceramic wire cutter;

Hydraulic system pipeline and hydraulic equipment pressure measurement control;

Pressure measurement and control of indoor and outdoor high-pressure water pump and other equipment;

Application fields:

-

Oil pressure system

-

Ceramic cutting

-

Water cutter equipment

-

Petroleum Pipeline

-

High pressure pump

-

Hydraulic equipment

Ordering considerations

Precautions for ordering PT500-702S products

1. Product range selection:

In order to achieve the best effect of product accuracy, life, stability and other functions, the range selection of the product is calculated by referring to the following formula:

Range = x (1.2-1.5) times of the maximum system pressure;

The actual measuring pressure range of the product should be 15% - 80% of the range;

2. Product power supply and output:

The selection of power supply range is determined according to the output specifications of the product:

Conventional 4-20mA, DC 12-30vdc power supply;

Display header, four places, one decimal place;

3. The user should understand the measurement medium characteristics of the product:

Medium specification, medium temperature, medium purity (whether containing impurities or particles, etc.);

4. Users should understand the installation environment and installation mode of the product:

Indoor or outdoor installation;

Ambient temperature;

Required sealing level;

Vibration range of equipment;

Pressure seal: taper seal, face seal, arc seal, spherical seal;

Whether the installation space meets the overall dimension of the product;

Precautions for use

PT500-702S waterproof high pressure transmitter

Product power supply 24VDC (range: 9-30vdc);

It is strictly prohibited to use hard objects (such as screwdriver, finger, iron nail, etc.) to make the pressure core body under pressure measurement output;

The power and signal wires shall be correctly wired according to the specifications of the ordered products;

When the product is installed, the stressed part is "process connection hexagon wrench position", and the wrench specification corresponds to hexagon;

It is strictly prohibited that the medium temperature, pressure range and excitation voltage of the tested system exceed the rated use range of the transmitter;

Pay attention to protect the outgoing cable of the transmitter. When the span is too large on site, it is recommended to use metal pipe for protection or overhead;

The product is installed in a ventilated, dry and non corrosive environment, and installed in the open with protective devices to avoid direct sunlight;

Red copper material is used for sealing parts of high-pressure products; for high-pressure products, attention shall be paid to protect the products during commissioning and use, so as to avoid damaging the surrounding personnel or equipment due to pressure leakage during commissioning or use;

Try to avoid direct access to user devices or electrical appliances that cause interference;