Chip:

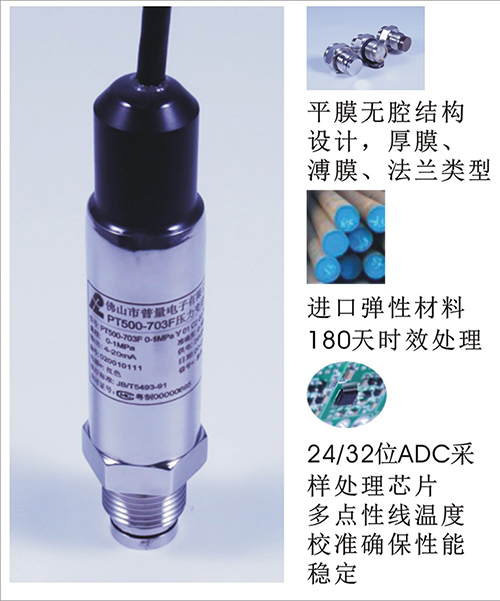

Flat film / diaphragm pressure sensing and anti blocking structure design, suitable for melt / fluid medium;

Adopt imported pressure sensitive chip; select the chip technology;

High impedance, high precision and high stability;

Diaphragm structure: thick film piezoresistive, thin film

silicon chip, flange type large diaphragm;

More than 1 million service life;

Signal processing and output:

24 bit ADC sampling processing chip;

DSP digital signal conditioning algorithm;

Multipoint line temperature calibration;

Voltage and current overload protection;

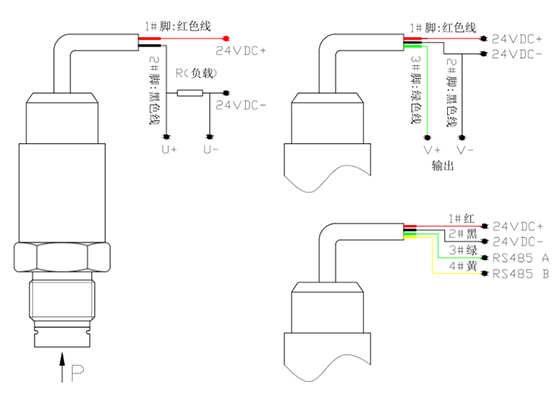

Standard industrial signal output: 4-20mA (two-wire system), 0-20mA (three wire system), 0-5vdc, 0-10vdc, 0.5-4.5vdc (three wire system);

Digital communication signal output: rs485-rtu, ultra-low power rs485-rtu

Advanced 32bit microprocessor and 24bit ADC

The transmission protocol adopts the general MODBUS-RTU protocol

Support baud rate: 1200 ~ 57600bps, check bit: none, odd, even

It supports the user's secondary calibration, clearing, anti clearing, factory restoration and other operations

Supports 11 unit switches, floating point, integer, percentage, format output

The acquisition interval of 0-43200 seconds (12 hours) can be set, which can not only continuously acquire, but also meet the occasion of high-speed acquisition, and can trigger acquisition once, minimizing power consumption

Structure:

Thick film structure: deep argon arc welding, connecting elastic material and process joint, high strength, impact resistance, fatigue resistance;

Thin film structure: laser welding, connecting elastic materials and process joints, silicon oil medium transfer pressure, fast response, fatigue resistance, small range;

Fully sealed waterproof outlet structure, suitable for outdoor, underwater, immersion and other working conditions;

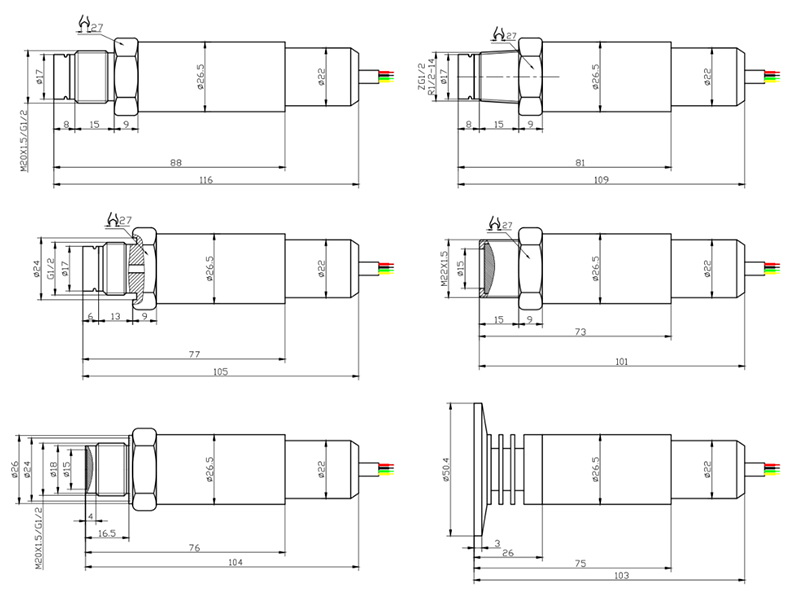

The overall structure is small and the process connection mode is diversified (m20x1.5, G1 / 2, ZG1 / 2, 1 / 2NPT (thread diameter ≥ 17mm) DN50, etc.);

Process connection material: 304 or 316;

Application:

Melt / fluid / viscous medium pressure measurement and control;

Equipment pressure measurement in industry / power / oil / automation and other fields

Intelligent fire control

Smart city

Steam supply system

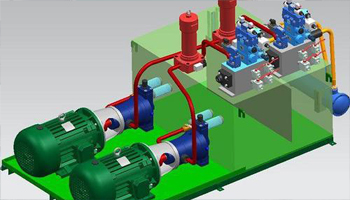

Oil pressure system

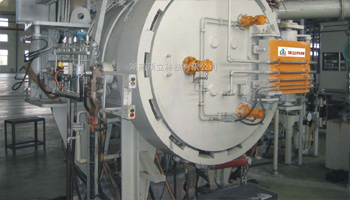

Metallurgical equipment

Fire fighting system