Product description of strain type pressure transmitter:

PT500-DAVS Pressure Transmitter

It adopts pure domestic pressure sensitive chip and selective placement technology;

High precision, stable, digital calibration adjustment, amplification integrated circuit;

Output signal 4-20mA two-wire system;

It can replace Hirschmann Davs series products;

M12 integrated connector;

Common keywords:

Davs pressure transmitter replaces Davs transmitter replaces Davs transmitter

Hirschmann sensor Hirschmann transmitter

Chip:

Pure domestic pressure sensing chip is used;

The selected placement process;

Zero point, fullness, temperature compensation and linear compensation;

High impedance, high precision and high stability;

More than 1 million times of service life;

Signal processing and output:

24 bit ADC sampling and processing chip;

DSP digital signal conditioning algorithm;

Multipoint linear temperature calibration;

Voltage and current overload protection;

Standard industrial signal output: 4-20mA (two-wire system), 0-20mA (three wire system), 0-5vdc, 0-10vdc, 0.5-4.5vdc (three wire system);

Advanced 32 bit microprocessor and 24 bit ADC are adopted

Structure:

Thick film structure: deep argon arc welding, connecting elastic material and process joint, high strength, impact resistance and fatigue resistance;

PU film structure: laser welding, connecting elastic material and process joint, transmitting pressure with silicone oil medium, fast response, fatigue resistance, small range;

304 / 316 shell, reliable and strong strength;

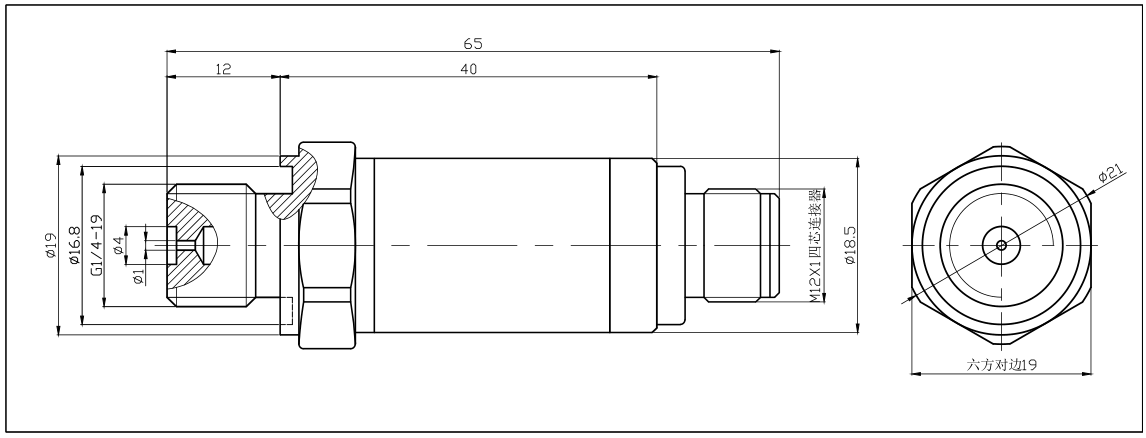

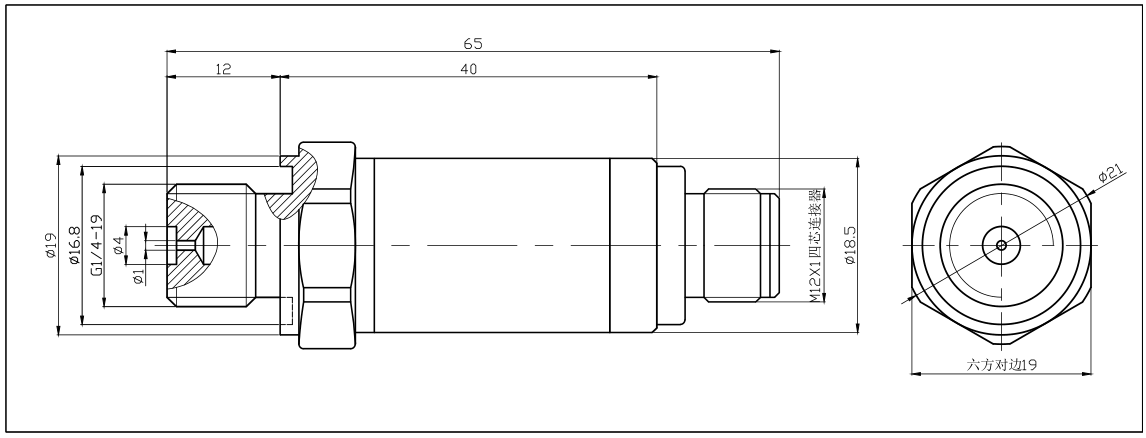

The overall size is 19x in diameter and 65mm in length. The process connection standard is G1 / 4;

Process connection material: 304 or 316;

Application:

Measurement and monitoring of oil pressure, water pressure and air pressure;

Equipment pressure measurement in industrial / power / Petroleum / automation fields;

Application fields:

-

Smart city

-

Oil pressure system

-

Metallurgical equipment

-

petrochemical industry

-

Water supply equipment

-

Hydraulic equipment

Specification parameter

Main technical parameters of pt500-davs pressure transmitter:

Measuring medium: liquid, gas, steam, etc

Pressure form: gauge pressure

Range: 0~60bar;

0~300bar;

0~400bar;

0~600bar�;

Comprehensive accuracy: ± 0.1% FS; ± 0.25% FS; ± 0.5% FS;

Nonlinearity: ≤ 0.25% FS

Repeatability: ≤ 0.1% FS

Output signal: current type: 4-20mA two-wire system;

Power supply voltage: 24 VDC (9 ~ 30 VDC)

Service life: ≥ 1 million times

Insulation impedance: ≥ 1000 m Ω / 100VDC

Load impedance: current output: ≤ 800 Ω;

Medium temperature: - 20 ~ 80 ℃

Ambient temperature: - 40 ~ 70 ℃

Compensation temperature: 0 ~ 70 ℃

Response time: ≤ 5ms

Overload pressure: 150% FS

Failure pressure: 3 times of measuring range (less than 40MPa); 2 times of measuring range (measuring range greater than 41mpa)

Electrical connection: Waterproof tight wire nut directly leads out, can be matched with explosion-proof electrical connection

Protection grade: IP68

Connecting cable: M12 aviation connector

Connection material: 304 / 316L

Process connection: G1 / 4

Ordering considerations

Precautions for ordering PT500-DAVS products

1. Product range selection:

In order to achieve the best effect of product accuracy, life,

stability and other functions, the range selection of the

product is calculated by referring to the following formula:

Range = x (1.2-1.5) times of the maximum system pressure;

The actual measuring pressure range of the product should be 15%

- 80% of the range;

2. Product power supply and output:

The selection of power supply range is determined according to

the output specifications of the product:

Conventional 4-20mA output, DC 12-30vdc power supply;

3. The user should understand the measurement medium

characteristics of the product:

Medium specification, medium temperature, medium purity (whether

containing impurities or particles, etc.);

4. Users should understand the installation environment and

installation method of the product:

Indoor or outdoor installation;

Ambient temperature;

Required sealing level;

Vibration range of equipment;

Installation method: thread, flange, special structure;

Whether the installation space meets the overall dimension of the product;